Glass vacuum tubes are essential in creating controlled environments for precise distillation, extraction, and analytical processes. At-Mar Glass manufactures each tube from high-grade borosilicate glass, ensuring exceptional clarity, strength, and consistency. Trusted by research institutions and industrial laboratories for over half a century, we deliver precision glassware that meets the highest scientific standards.

In advanced laboratory environments, laboratory vacuum tubes are indispensable for processes that demand precise pressure control and contamination-free conditions. Their design allows scientists to replicate and study chemical reactions under reduced pressure, enhancing both the accuracy and efficiency of experimental results.

Vacuum tubes make it possible to carry out distillation and extraction at lower temperatures, preserving the integrity of sensitive compounds that might otherwise degrade under heat. By maintaining a consistent vacuum, they allow solvents to evaporate efficiently while minimizing oxidation and thermal stress. This makes them a critical component in pharmaceutical formulation, organic synthesis, and analytical chemistry.

From university research labs to large-scale production facilities, vacuum tubes play a central role in analytical testing, material synthesis, and environmental analysis. Their precision and uniformity support reproducible outcomes, which is vital in regulated industries where consistency defines credibility. At-Mar Glass designs its equipment to integrate seamlessly with existing manifolds and distillation systems, supporting a range of scientific disciplines.

At the core of every At-Mar design is the use of borosilicate vacuum tubes, valued for their chemical resistance and ability to withstand rapid temperature fluctuations. This material ensures long-term reliability and clarity even under continuous use in demanding laboratory conditions. The result is a piece of equipment that offers both performance and resilience — fundamental attributes for professional research operations.

Every detail in the construction of borosilicate vacuum tubes influences performance, reliability, and safety. At-Mar Glass engineers each tube for strength, clarity, and chemical resistance—qualities essential to maintaining precision in advanced laboratory environments.

At-Mar’s glassblowers maintain strict tolerances for wall thickness, joint dimensions, and surface finish. This precision ensures a consistent vacuum seal and compatibility with standard laboratory manifolds and fittings. The result is dependable performance, even in continuous-use or high-temperature applications.

Borosilicate glass is the preferred material for laboratory vacuum applications due to its resistance to thermal shock, corrosion, and chemical attack. Its non-reactive nature prevents cross-contamination and allows for safe handling of reactive solvents, acids, and organic compounds—extending the functional lifespan of each tube.

Recognizing that every laboratory setup has unique requirements, At-Mar Glass offers complete customization for tube dimensions, joint types, and connection styles. Whether adapting to an existing manifold or developing an entirely new apparatus, our specialists can fabricate equipment tailored to precise operational needs.

When standard dimensions don’t meet experimental requirements, custom glass vacuum tubes from At-Mar Glass provide the flexibility and precision today’s laboratories demand. Our in-house team combines decades of experience with modern fabrication tools to produce specialized equipment that meets exact specifications and performance standards.

Every piece begins with skilled scientific glassblowing, performed entirely at our Kennett Square facility. Our craftsmen shape, fuse, and anneal each component to achieve precise geometries and vacuum integrity. This hands-on process ensures superior quality control—something mass-produced alternatives simply can’t match.

We collaborate directly with research teams, engineers, and procurement specialists to turn technical drawings or sketches into functional, laboratory-ready assemblies. Whether modifying a joint size, altering a port configuration, or building an entirely new design, At-Mar Glass delivers equipment that integrates seamlessly into existing systems.

Because all fabrication and finishing are handled in-house, lead times remain short and communication straightforward. Urgent repairs or last-minute design changes can often be accommodated within days, not weeks. Each order receives personal attention from our team—ensuring every customer receives equipment that performs exactly as intended.

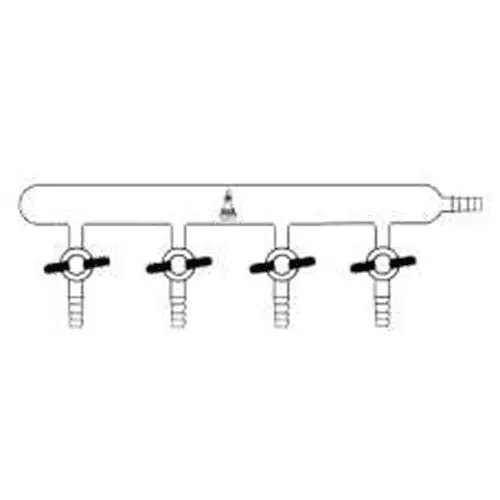

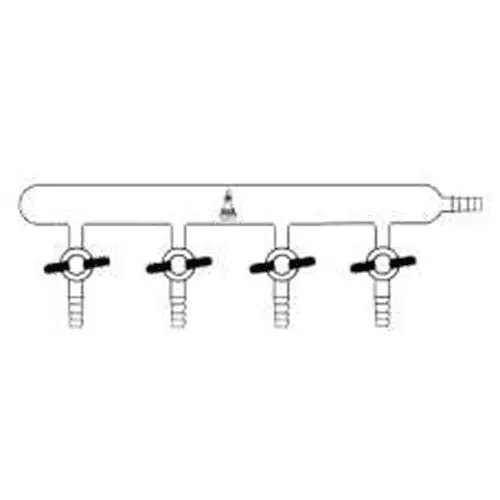

At-Mar’s vacuum manifold tubes are engineered for seamless compatibility with modern laboratory systems, ensuring reliable performance across a variety of analytical and distillation setups. Each component is designed to fit precisely with industry-standard joints and connectors, promoting efficiency and versatility in complex lab environments.

Our glass vacuum tubes are built to interface easily with manifold assemblies, condensers, and adapters used in vacuum distillation apparatus configurations. This compatibility allows laboratories to process multiple samples at once, optimizing workflow without sacrificing control or accuracy.

Ease of use is central to At-Mar’s design philosophy. Each tube can be assembled or disassembled quickly, enabling technicians to clean, inspect, or reconfigure equipment between experiments with minimal downtime. Precision ground joints and uniform tolerances ensure secure connections that maintain vacuum integrity during operation.

The smooth interior surfaces of our tubes minimize residue buildup and cross-contamination, reducing the risk of compromised samples. This design efficiency not only safeguards the purity of research outcomes but also extends the life of each component—helping laboratories maintain consistent performance under demanding conditions.

To meet the diverse requirements of modern laboratories, At-Mar Glass manufactures several configurations of vacuum tubes. Each design supports specific applications—offering durability, clarity, and performance suited for analytical, research, and industrial use.

Every laboratory vacuum tube produced by At-Mar Glass is designed with user safety and product longevity in mind. Our optional protective coatings and stringent quality-control protocols ensure that each piece of glassware performs consistently, even in demanding laboratory environments.

At-Mar’s proprietary safety coatings add an extra layer of protection against breakage and chemical exposure. In the event of accidental impact, the coating helps contain glass fragments and minimize the risk of injury. Its chemical resistance also prevents surface degradation, extending the lifespan of the glassware under frequent use.

Our coatings and borosilicate construction work together to reduce the risk of contamination from reactive substances or cleaning solvents. The nonporous, stable surface maintains sample integrity throughout experiments—an essential factor for laboratories that rely on precise analytical results.

Every piece of equipment is inspected multiple times during production to verify dimensional accuracy, surface integrity, and vacuum performance. By maintaining full control over fabrication and testing in our Kennett Square facility, At-Mar Glass ensures that customers receive laboratory glassware that meets both internal specifications and the highest industry standards.

For laboratories that depend on precision equipment, the choice of manufacturer directly impacts research quality and workflow efficiency. At-Mar Glass combines technical mastery, responsive service, and decades of specialized experience to deliver glassware that consistently exceeds expectations.

With over fifty years of continuous operation, At-Mar Glass has refined every stage of scientific glass production. Our team of master glassblowers blends traditional craftsmanship with modern technology to produce equipment that performs reliably under rigorous laboratory conditions.

All design, fabrication, and finishing take place at our Kennett Square, Pennsylvania facility. By keeping production in-house, we maintain full control over quality and turnaround times—ensuring that every order meets exacting standards without the delays or variability that often come from outsourcing.

Whether fulfilling a bulk order or crafting a single specialized piece, our team works directly with clients to understand their goals and challenges. Fast response times, clear communication, and attention to detail make At-Mar a trusted partner for research institutions and industrial labs across the United States.

We believe that high-quality glassware should be accessible to every professional lab. At-Mar Glass delivers premium craftsmanship and reliability at competitive pricing, ensuring exceptional value without compromising precision or safety.

Choosing the right vacuum tubes for your laboratory setup can raise technical questions about materials, performance, and customization. Below are answers to some of the most common inquiries we receive from researchers, engineers, and lab managers regarding our precision-made glass vacuum tubes.

Glass vacuum tubes create controlled, low-pressure environments required for distillation, extraction, and chemical synthesis. By eliminating atmospheric interference, they enable precise temperature control and preserve the integrity of heat-sensitive compounds.

Borosilicate glass offers exceptional resistance to thermal shock and chemical corrosion. Its durability and stability under extreme conditions make it ideal for continuous laboratory use while maintaining optical clarity and structural integrity.

Yes. Our in-house glassblowing experts can fabricate custom assemblies from your drawings, measurements, or specifications. Whether you require non-standard joint sizes, additional ports, or unique manifold connections, we can design and build glassware tailored to your needs.

Absolutely. We offer optional protective coatings that contain fragments in the event of breakage and resist chemical damage. These coatings enhance user safety, simplify handling, and extend the lifespan of each glass component.

Because all production takes place in-house at our Kennett Square facility, most standard orders are fulfilled promptly. Repairs or smaller fabrication projects can often be completed within just a few days, minimizing downtime for active laboratories.

Yes. Our tubes are manufactured to industry-standard dimensions, ensuring seamless compatibility with existing vacuum manifold tubes and related lab equipment. This allows users to replace or expand system components without costly redesigns or delays.

When precision and reliability matter most, turn to the experts at At-Mar Glass. Whether you need standard glass vacuum tubes or custom-fabricated designs built to your exact specifications, our team is ready to help. Call us today or request a quote to discuss your requirements and experience the craftsmanship, responsiveness, and quality that laboratories worldwide have trusted for over fifty years.